Understanding Game Card Printing Costs

Creating custom game cards requires careful planning and budgeting. One of the most crucial considerations for designers, publishers, and hobbyists is understanding game card printing costs. These costs influence the quality, quantity, and overall feasibility of a project, and a clear understanding helps in making informed decisions while ensuring the final product meets expectations.

Factors Affecting Game Card Printing Costs

Several variables determine the overall expenses associated with printing game cards. Understanding these factors allows businesses and individuals to optimize both quality and budget. The main elements include material quality, printing method, card size, and quantity.

Materials play a significant role in pricing. Premium cardstocks, coatings, and finishes enhance durability and appearance but often increase costs. Standard cardboards are more affordable but may not provide the same feel or longevity.

Printing methods, such as offset or digital printing, also impact costs. Offset printing is more cost-effective for large runs, while digital printing is suitable for smaller batches or highly customized designs. Each method has its advantages and price considerations.

Quantity and Bulk Pricing

The number of cards being produced significantly affects game card printing costs. Generally, higher quantities lead to lower per-unit costs due to economies of scale. Small print runs are more expensive per card but allow for flexibility in testing designs or producing limited editions.

Manufacturers often provide tiered pricing based on volume. Understanding these pricing structures can help clients plan budgets effectively and avoid unexpected expenses.

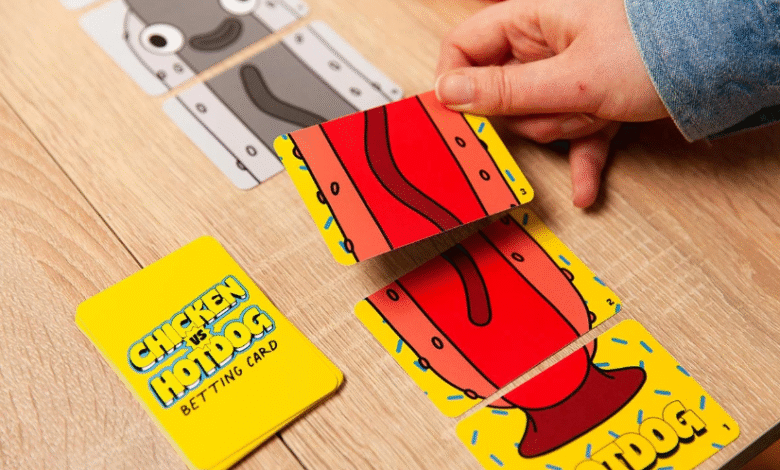

Customization and Design Complexity

Custom designs and intricate artwork increase game card printing costs. Features such as full-color images, intricate illustrations, custom fonts, or unique layouts require more time and precision during production.

Additional customization, including embossing, foil stamping, or specialty coatings, adds to the overall cost. A well-balanced approach ensures that the design meets aesthetic goals without excessively increasing expenses.

Card Size and Shape

The dimensions and shape of game cards influence production costs. Standard sizes are generally more affordable, while unusual shapes or oversized cards may require custom dies, increasing costs.

A custom card shape can enhance the game’s uniqueness but requires careful consideration of budget implications. Discussing options with a printing professional helps balance creativity and cost-efficiency.

Finishes and Coatings

Protective finishes such as gloss, matte, or soft-touch coatings contribute to both appearance and durability. Specialty finishes, including UV coating or linen texture, enhance visual appeal and tactile experience but increase game card printing costs.

Selecting the appropriate finish depends on the game’s target audience, usage, and budget. Durable finishes are particularly important for games that are frequently handled or transported.

See also: Understanding Uncomfortability: More Than Just Feeling Awkward

Packaging and Presentation

Packaging is another factor that affects overall game card printing costs. Boxes, tuck cases, or custom packaging solutions require additional materials and labor. Packaging not only protects the cards but also contributes to the perceived value of the product.

A thoughtfully designed package can create a professional impression, but designers must account for its impact on production budgets. Bulk packaging options or standard sizes may help reduce costs without compromising quality.

Choosing the Right Manufacturer

Selecting a reliable printing partner is essential for managing game card printing costs. Experienced manufacturers can offer guidance on materials, printing methods, and cost-effective solutions tailored to the project’s requirements.

Comparing quotes, reviewing previous work, and understanding turnaround times ensures that the project stays within budget while achieving game card printing costs desired quality standards. Collaborating closely with a manufacturer helps avoid unnecessary expenses and production delays.

Strategies to Reduce Costs

Several strategies can help minimize game card printing costs without sacrificing quality. Producing larger quantities reduces the per-unit price, and opting for standard sizes or materials can save money. Simplifying design elements or limiting specialty finishes also lowers costs.

Digital proofs and prototypes help identify potential issues early, avoiding costly mistakes during full production runs. Planning ahead and clearly defining project requirements are key strategies for controlling expenses.

Balancing Quality and Budget

Balancing quality and cost is critical in game card production. High-quality cards enhance gameplay experience, customer satisfaction, and product longevity. Cutting corners may reduce initial expenses but can affect durability and player perception.

A well-planned approach involves assessing the project’s priorities, evaluating options for materials, printing, and finishes, and making informed decisions that align with both aesthetic and financial goals.

Conclusion

Understanding game card printing costs is essential for producing high-quality, custom game cards. Multiple factors influence expenses, including materials, printing methods, quantity, design complexity, card size, finishes, and packaging.

Collaborating with an experienced printing partner allows designers and businesses to optimize these factors, ensuring a cost-effective solution that does not compromise on quality. By carefully planning each aspect, it is possible to produce game cards that are visually appealing, durable, and within budget, providing a professional and enjoyable experience for players.